Our Service Areas

If you need furnace repairs or air conditioner replacements, you need to schedule services with a trusted local expert. Call our experts at DiBiase Heating and Cooling Company for appointments in Downingtown, PA. We offer 24/7 services for your convenience!

Our experienced HVAC technicians can quickly and accurately identify problems with your system and get it up and running again to restore comfort to your house. We provide the ultimate customer experience in Downingtown, PA, and beyond!

We value our customers’ feedback. Read our testimonials to see what they think of our work.

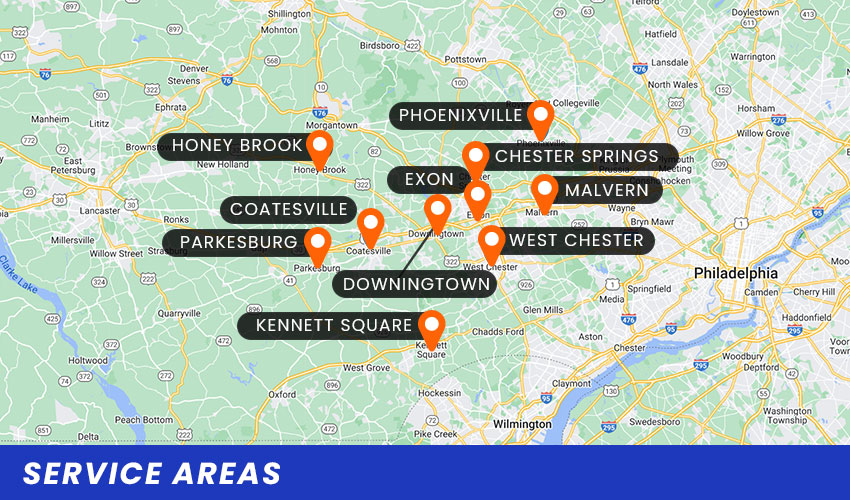

Proudly Serving Downingtown, PA, & Surrounding Areas

DiBiase Heating and Cooling Company provides quality heating and cooling services in the following areas:

- Downingtown: Heating | Cooling

- Honey Brook: Heating | Cooling

- Exton: Heating | Cooling

- Chester Springs: Heating | Cooling

- West Chester: Heating | Cooling

- Coatesville: Heating | Cooling

- Phoenixville: Heating | Cooling

- Malvern: Heating | Cooling

- Parkesburg: Heating | Cooling

- Kennett Square: Heating | Cooling